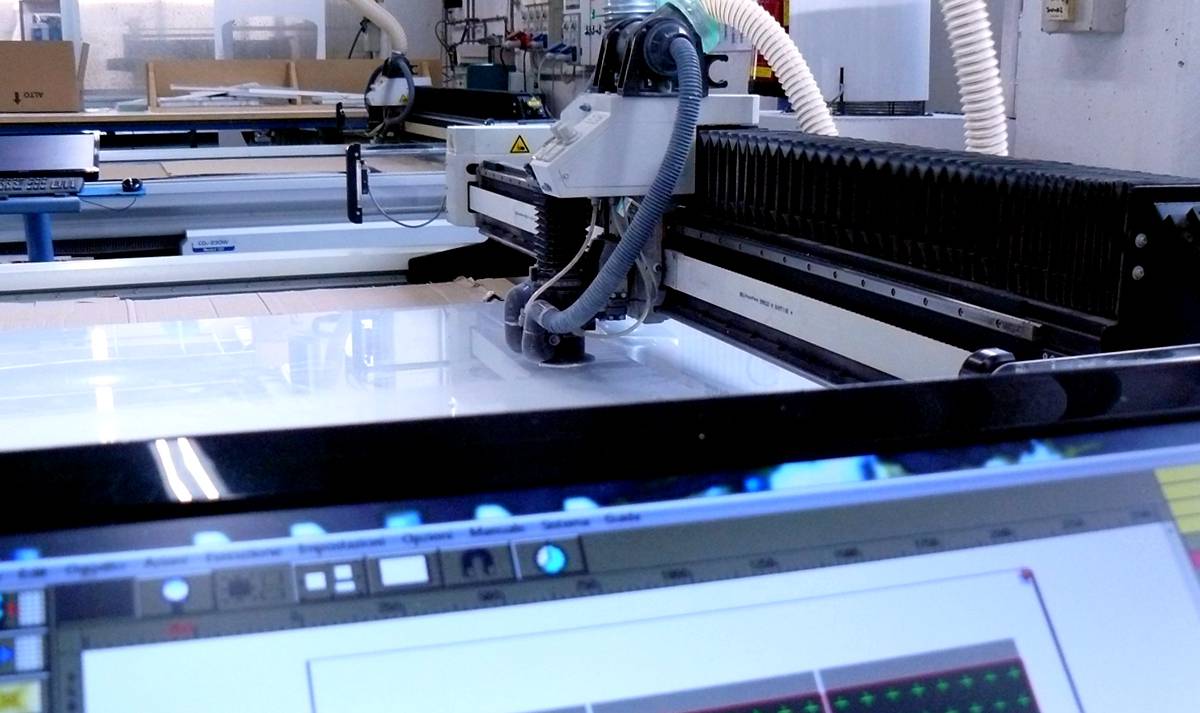

LASER CUTTING AND ENGRAVING

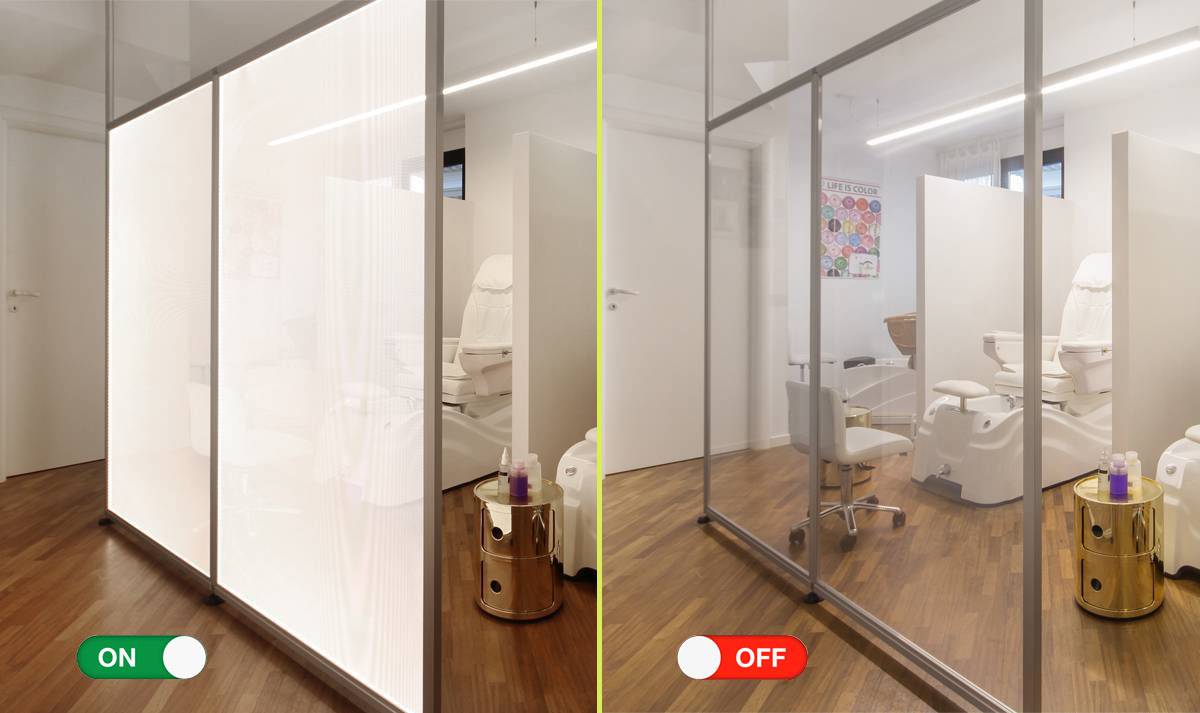

FIRMA performs laser processing on PMMA and other plastic materials thanks to two laser stations dedicated to cutting, drilling and laser engraving, as well as having equipped these lasers with software for the realization of light panels made to measure thanks to the backlight technology optimized by our technicians.

LASER CUTTING: Allows to obtain glossy edges, without smudging and a reduced thermal alteration of the material.

LASER DRILLING: It makes possible the realization of shiny holes, very small and very precise with a variety of shapes.

ENGRAVING | LASER MARKING: Thanks to the laser technology it is possible to affect the material with different intensities, thus creating images or writings decided or with various shades.

EN

EN IT

IT DE

DE FR

FR