| Client: | Italian and Foreign companies of Packaging and Medical Industries |

| Where: | Italiy + World |

| When: | 1993 / ongoing |

| Design: | Technical drawings provided by the customer. |

| Photography: | Federica Manenti FIRMA |

STRENGHTS

PRECISION + QUALITY

Tolerances to the hundredth of a millimeter on lid measures and precision grinding of the thickness, along with color customization and highest quality in polishing and machining, make our covers the best product on the market.

Strong know-how gained through years of experience in industrial applications, FIRMA provides maximum professionalism and quality, also offers its customers more than 40 proprietary molds.

Today FIRMA produced vacuumtight lids, both flat and domed, of all sizes up to reach:

thickness 40 mm

length of 1150 mm

width 850 mm

dome depth 0-160 mm

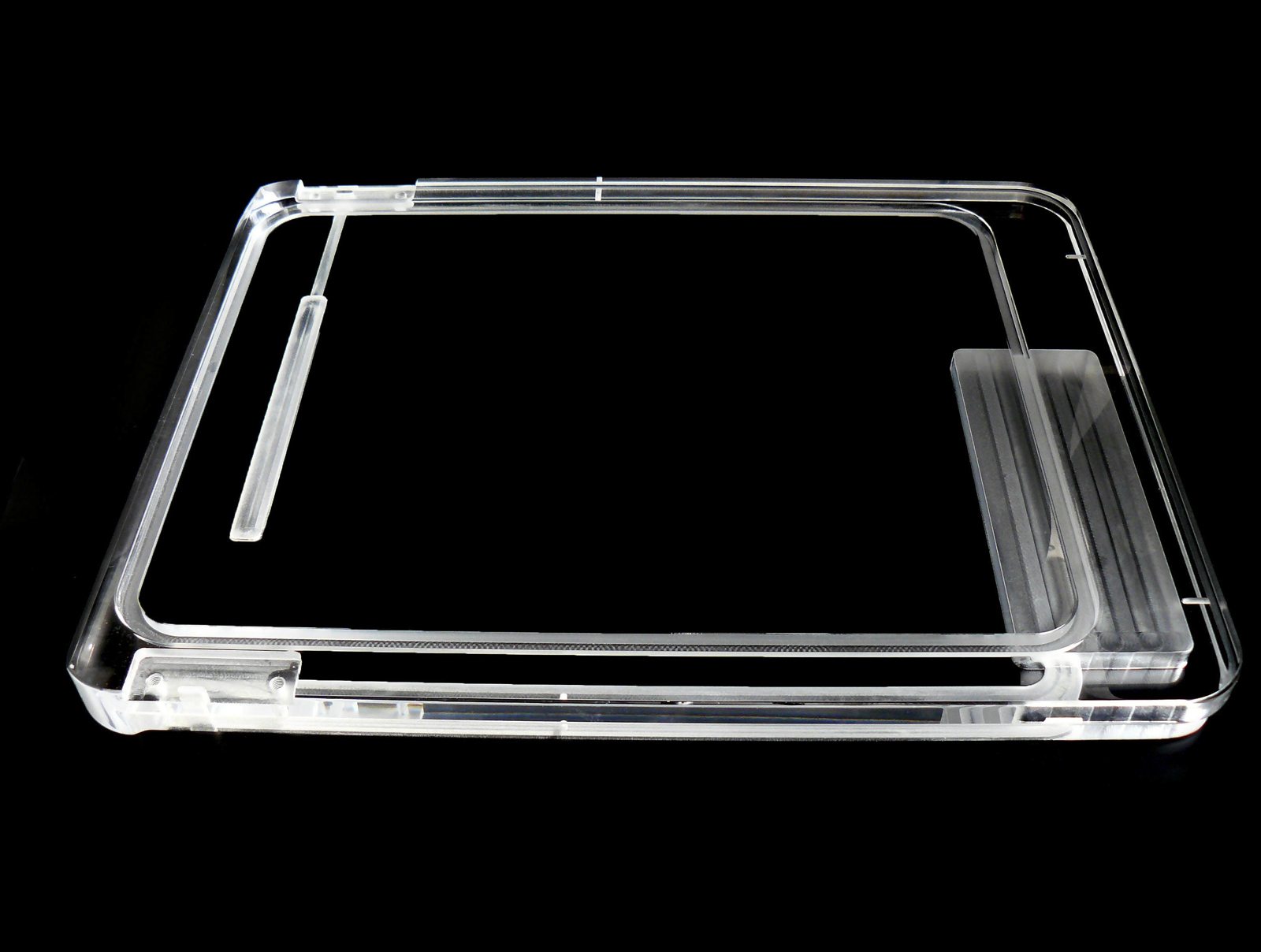

Internal section of a vacuum lid at the end of the production process that includes: thermoforming, CNC machining, grinding of the thickness, polishing, cleaning and quality control.

Vacuum lid at the end of the production process that includes: thermoforming, CNC machining, grinding of the thickness, polishing, cleaning and quality control.

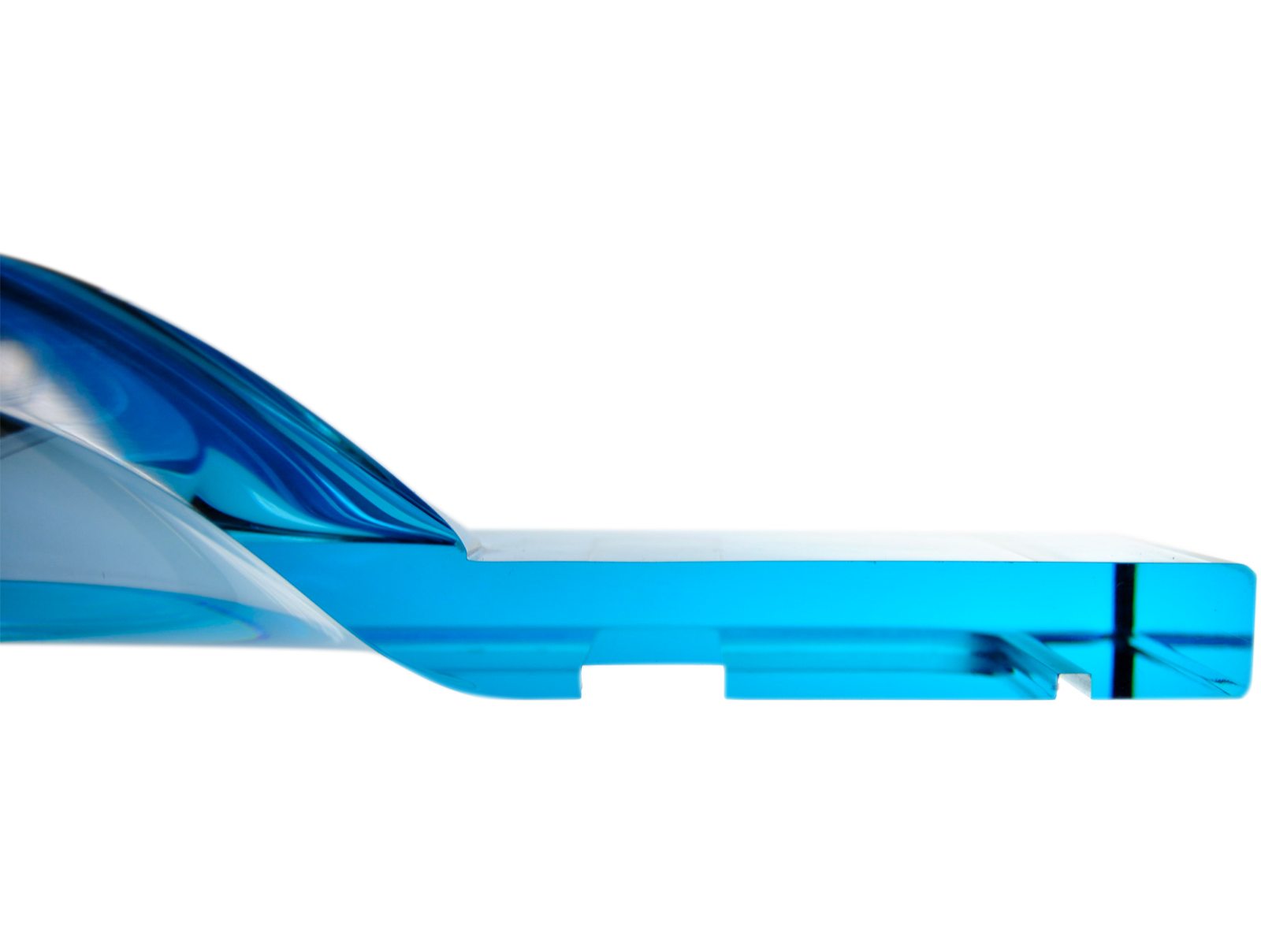

Storage of acrylic blu vacuum lids awaiting subsequent processing and quality control.

Technical manual processes.

Manual polishing phase.

Flat vacuum lid at the end of the production process that includes: CNC machining, grinding of the thickness, polishing, cleaning and quality control.