FIRMA is an Italian precision CNC machining facility. With a focus on continuous improvement, we strive to provide our customers with the best experience possible by delivering high quality plastic parts.

Learn more about our TECHNOLOGIES

CNC turning of plastic and high-tech polymers has become essential to the manufacturing sector. This subtractive manufacturing process often pairs expert designers and engineers with the most advanced equipment available to create plastic parts and components with extremely intricate or complex geometries.

Here you find a one-stop machine shop for CNC turning services using CNC lathes with live tooling for custom parts.

CNC turning services are necessary to produce precision machined plastic parts or components for nearly every industry, including industrial, lighting, medical, automotive and electronics.

CNC TURNING SERVICE AND LATHE TURNED PARTS

CNC lathes and turning machines rotate the workpiece while the cutting tool removes material around the outer diameter to produce the desired component.

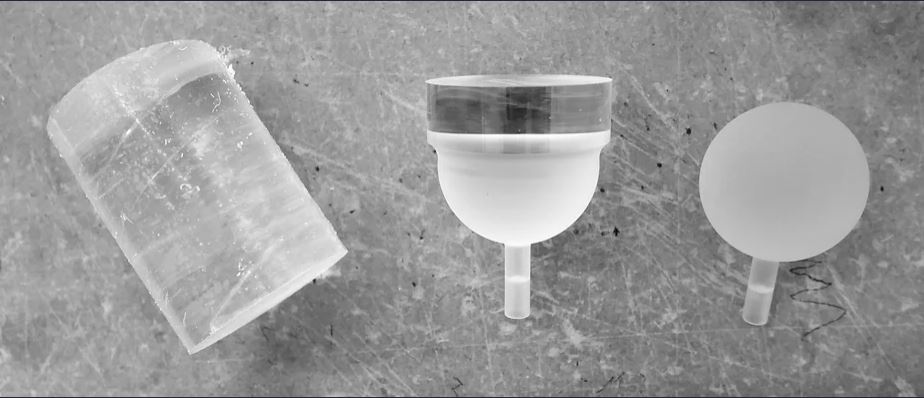

FIRMA is a professional manufacturer specialized in CNC turning of plastics and engineering polymers such as Delrin - POM-C, PE, Nylon, PMMA, PVC

There are many types of CNC turning operations for CNC lathe services can be performed on a live tooling lathe in CNC turning factory, including Hard turning, Parting, Facing, Boring, Reaming, Taper turning, Drilling, Knurling, Threading, Grooving, etc.

-

Tapered turning: produce a cylindrical part of which diameter decrease from one end to another.

-

Spherical generation: create a spherical finished surface, turning around fixed rotary axis.

-

Facing: a turning operation in which the workpiece is machined to its center.

-

Parting: create deep grooves that remove a completed or part-complete component from its parent stock.

-

Grooving: similar to parting, but only cut to a specific depth from outside or inside of workpiece.

-

Drilling: remove materials to drill holes from the inside of a workpiece with drill bits held stationary in the tail stock or tool turret of the lathe. Boring: enlarge or smooth an existing hole.

-

Knurling: cut serrated pattern onto the surface of workpiece with knurling tool, to change or enhance visual effect or hand grip.

-

Reaming: remove a small volume of materials from a drilled hole, for highly accurate diameters.

-

Threading: turn standard and non-standard screw threads, generally means single-point threading.

CNC turning and precision machining produces parts to a much more exacting standard than baseline CNC machining. It is an excellent solution to meet stringent project requirements.

Learn more about our technologies

FIRMA carries out CNC turning and CNC precision machining of plastic and high-tech polymers

Contact us now

+39 035 58 06 57

EN

EN IT

IT DE

DE FR

FR